Designed for Healthcare Productivity

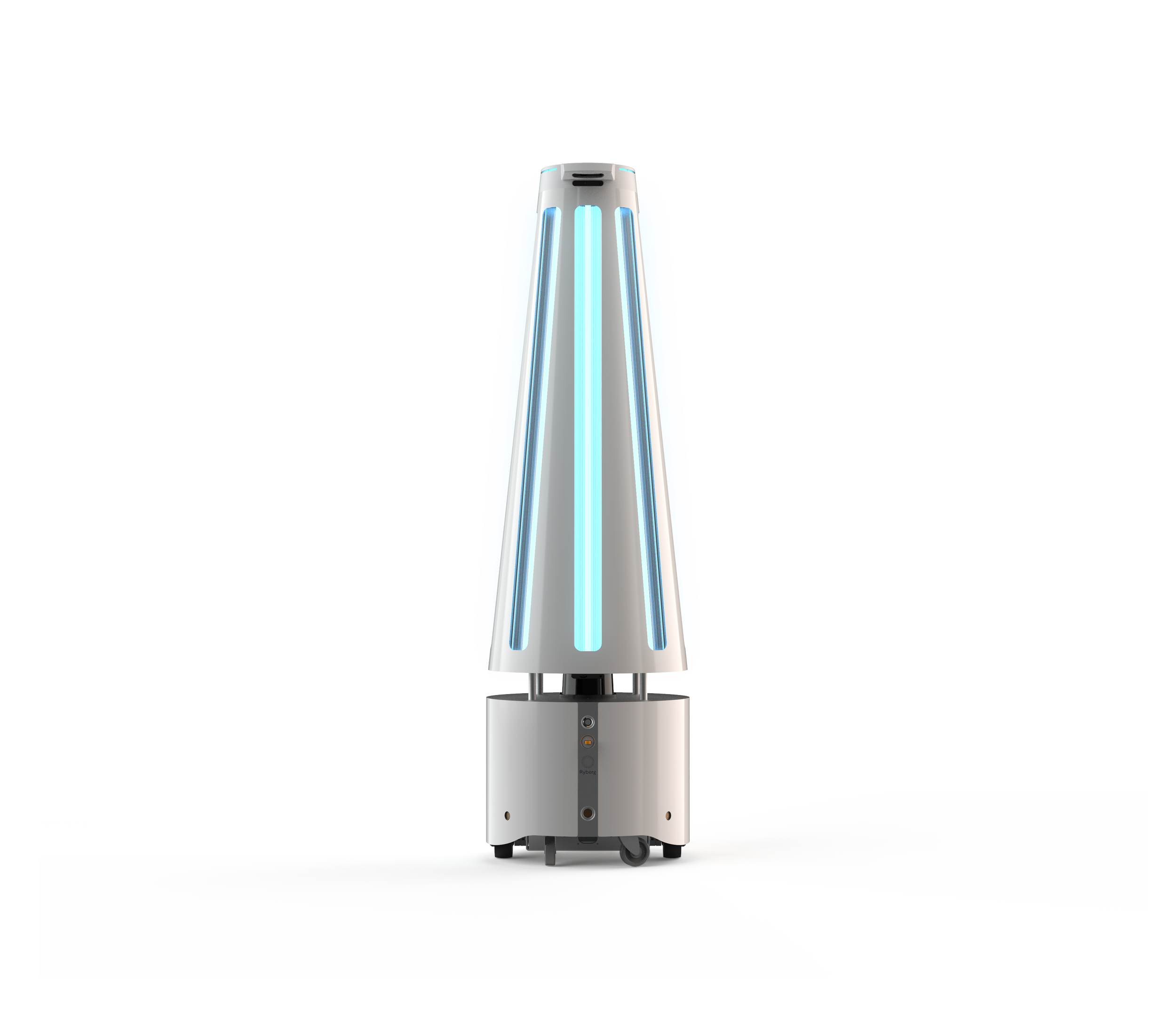

Omnia UV-C Disinfection Robot

-

Ryberg’s Omnia robots seamlessly integrate into healthcare processes, improving actionability and speed, free up staff for higher-value tasks, and optimize overall hospital efficiency.

-

Omnia delivers consistent, automated disinfection, maximizing room turnaround times, and fostering a safer environment for patients and staff.

-

Omnia's modular design allows hospitals to adapt their disinfection strategy as needs evolve, ensuring long-term efficiency and cost-effectiveness.

Key benefits

Uniquely Designed for Hospitals

Designed from scratch

for operations in hospitals.

Intelligently Engineered

Navigates in narrow spaces, where competitors can’t.

Hospital-grade Disinfection

Mitigates human disinfection inconsistency.

Sustainable Disinfection

Combats hospital-acquired-infections with a safe,

effective non-chemical solution.

User-Intuitive

Easy-to-use for all staff,

minimizing human error.

Digital Reporting

Detailed disinfection reports for transparency and compliance

CB Certified by DEKRA

Harmonizes with international safety standards

Made in The Netherlands

Designed and developed by team from TU Delft

The Power of Intelligent Disinfection

-

Automation frees staff for higher-value tasks, potentially reducing reliance on temporary workers. Predictable disinfection allows for optimized scheduling and resource allocation.

-

Ryberg robots ensure consistent disinfection times through automated navigation, standardized cycles, and sensor-based adjustments. This translates to quicker room turnaround, improved scheduling, and reduced downtime.

-

COMPLIANCE

Ryberg’s UV-C disinfection robots are CB-Certified and designed to meet the strict standards set by Joint Commission International (JCI) for healthcare facilities. The robots use UV-C light to deactivate germs and bacteria on surfaces, making them a powerful tool for preventing the spread of infection.

REPORTING

Digital disinfection reports provide a clear and detailed record of the areas that have been disinfected, the time the disinfection took place, and the level of disinfection achieved. This transparency helps to ensure that the facility is meeting the required standards of cleanliness and safety, and it also allows for easy monitoring of the disinfection process. -

Ryberg's reporting system provides insights into cleaning cycles, empowering data-driven optimization of resources and audit compliance.

Management features

-

Our fleet management feature includes:

● Remote monitoring: Monitor and control multiple robots remotely from a single interface.

● Real-time status updates: View the status of each robot in real-time, including battery levels, cleaning progress, and error messages.

● Maintenance alerts: Receive alerts when it's time for regular maintenance, such as filter replacements or software updates.

● Performance tracking: Track and analyze the performance of each robot over time to identify trends and potential issues.

● Reports: Generate detailed reports on the performance and usage of each robot for better decision making.

● Remote support: Our team can connect remotely to each robot to diagnose and fix problems, if possible.

-

Our disinfection report feature includes:

● Detailed information: Reports include detailed information on the disinfection process, including the areas covered, time spent cleaning, and the intensity of the UV-C light used.

● Time-stamped reports: Reports are time-stamped, providing a clear record of when and where the disinfection took place.

● Accessible: Reports can be easily accessed and reviewed through a web-based interface.

● Compliance: Reports can be used to demonstrate compliance with disinfection protocols and regulations.

FAQs

-

1. Effectiveness: UV-C light has been proven to be an effective method for neutralizing pathogens, including bacteria, viruses, and other microorganisms.

2. Speed: Ryberg’s UV-C disinfection robots can disinfect large areas quickly and efficiently, reducing the time required for disinfection.

3. Safety: Ryberg’s UV-C disinfection robots do not use chemicals, reducing the risk of chemical exposure for both employees and patients.

4. Cost-effective: UV-C disinfection robots are a cost-effective solution, as they can be used for multiple rounds of disinfection, reducing the need for labour cost and chemical disinfectants.

5. Customizable: Ryberg’s UV-C disinfection robots can be customized to target specific pathogens and areas or surfaces, which can be particularly useful in situations where certain pathogens are known to be active and with areas or surfaces that are more likely to be contaminated.

-

The way UV-C disinfection robots work is by emitting a high-intensity UV-C light, which is able to penetrate the cell walls of microorganisms, damaging their DNA and rendering them unable to reproduce and infect. This process is known as "UV-C germicidal irradiation" and it's been proven to be highly effective in killing a wide range of microorganisms, including bacteria, viruses, and fungi.

-

Ryberg has worked closely with infection prevention specialists to test its UV-C disinfection robots in order to ensure their effectiveness and safety.

1. Protocol development: Ryberg works with infection prevention specialists to develop protocols for testing the robots' effectiveness in neutralizing pathogens.

2. Laboratory testing: The robots are tested in a laboratory setting using the protocols developed.

3. Field testing: The robots are also tested in real-world settings. This allows for testing in a more realistic environment and allows for the robots' effectiveness to be evaluated in a real-world setting.

4. Data analysis: The data collected from the laboratory and field testing is analyzed to determine the robots' effectiveness in neutralizing pathogens.

5. Continuous improvement: Ryberg works with infection prevention specialists to use the data collected to continuously improve the robots' performance.